A dental handpiece is to a dentist what a pen (or these days, a keyboard) is to a writer. It is the tool that enables the work many dental practitioners argue is more art than science. Choosing your dental handpieces, therefore, is a highly personal undertaking, requiring a fair amount of knowledge about what they’re made of and how each one works in different circumstances.

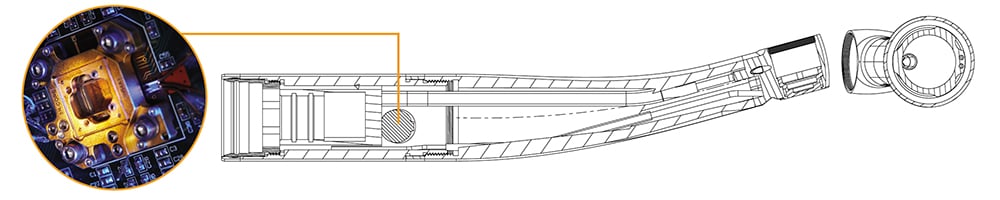

Dental handpieces consist of a handle, or housing, with a small head that accommodates a dental bur, used to perform various treatment and maintenance procedures on a patient’s teeth. Inside the handle are the many components that make the bur spin, and the components are powered by either compressed air or electricity. In this article, we will focus mainly on high-speed dental handpieces and electric dental handpieces with some discussion of low- or slow-speed handpieces. We will look briefly at the past, present and future of handpiece technology, and finally, provide tips for how to decide on the right dental handpieces for your practice.

History of Dental Handpieces

Little was known about the use of dental tools prior to 1728, when French physician Pierre Fauchard described the use of rudimentary in his groundbreaking book, The Surgeon Dentist. More recently, archeologists discovered evidence of tooth drilling with flint tips in stone age Pakistan and a few other more recent ancient civilizations.

Many online sources describe the evolution of dental handpieces starting in the 18th century, roughly following this timeline:

Around the time these air-driven handpieces were being developed, Star Dental was growing from a simple operation founded in 1911 to a key player in the dental handpiece market with a loyal customer base. Through close partnership with its customers and clinical advisors, DENTALEZ’s Star product line has contributed many important firsts to handpiece history:

- 1973: Integrated fiber-optic lighting

- 1979: Air-driven sonic scaler

- 1985: LubeFree low-speed dental handpiece

- 1986: Push-button auto chuck

- 1987: Quick disconnect back end

- 1987: Swivel back end

- 1991: LubeFree high-speed dental handpiece

- 2020: Intelligent RFID tracking for handpieces

You can read more details about these Star Dental handpiece innovations here and here.

Power Types for Dental Handpieces

As in all aspects of the modern world, current dental handpiece technology has advanced exponentially faster in the last century than at any time in history. As the chart above shows, the focus in handpiece development has long been increasing the rotational speed and torque of the cutting bur to make procedures quicker, more accurate and more comfortable for both patients and practitioners. Two types of power, compressed air and electricity, have proven superior in improving speed and/or torque, each of which has advantages and disadvantages.

Air-driven Handpieces

Air-driven dental handpieces contain an air turbine in the head. When compressed air delivered through a tube is forced through the blades of the turbine, the movement of the turbine converts that air pressure into the rotational force that makes the chuck (which holds the cutting bur) spin. A more detailed look at how air-driven handpieces work can be found here.

Pros:

- High-speed dental handpieces run at incredibly high speeds of 400,000-800,000 rpm, with operating speeds of 180,000-350,000 rpm.

- High speed results in faster, less painful removal of hard tissue.

- Low-speed dental handpieces operate at 100–20,000 rpm, useful for caries and soft tissue removal, as well as restorative work.

- Tend to be lighter and smaller with smaller head sizes to provide more visibility inside the oral cavity.

- Lower upfront and maintenance costs compared with electric handpieces.

Cons:

- Higher speed typically results in lower torque, which is a disadvantage when cutting through harder materials such as those used in crowns.

- O-Ring mount inside the handpiece head allows the bur to move somewhat during cutting, resulting in small vibrations that can cause cracking of enamel and jagged margins.

- Air-driven handpieces tend to produce the loud, shrill noise that makes some patients anxious.

Electric Handpieces

Electric dental handpieces, also called variable-speed handpieces, are powered by an electrical console with a touchscreen for controlling various aspects of the handpiece attachments. This console, or control unit, can be portable or mounted to a dental delivery system. The rest of the unit consists of a brushless motor, which receives power from the console through flexible tubing, and handpiece attachments that achieve different speeds through their internal gear design.

The motor has a gear, called the drive gear that runs at 100-40,000 rpm. The various handpiece attachments all have a gear as well, called the chuck gear, which is powered by the drive gear. The size of the chuck gear relative to size of the drive gear is what determines the rotational speed of the cutting bur. High-speed attachments have a chuck gear five times smaller than the drive gear, which increases Slow-speed handpieces have chuck gears that are larger than the drive gear, which decreases the speed of the bur. There are handpieces with ratios of 5:1, 8:1, 10:1 and even 20:1, each with a speed that is ideal for dental procedures where more torque are required, such as endodontic and surgical procedures. A closer look at electric handpiece design and maintenance can be found here.

Pros:

- Electric handpieces have higher torque, so a handpiece that runs at 200,000 rpm will not slow down when the bur makes contact with the tooth or other material to be cut, as it does with air-driven handpieces. This results in much easier cutting.

- Because of their internal design, they have better concentricity, resulting in cleaner margins.

- They are noticeably quieter than air-driven models.

- Control panel with presets allows you to set the speed without having to use a foot pedal.

Cons:

- Electric handpieces are heavier than air-driven handpieces with larger heads.

- They are still more expensive than air-driven models, although this may begin to change with greater adoption.

- They have many more internal moving parts, which are more difficult and costly to repair.

Current and Future Technology in Dental Handpieces

Current innovations in dental handpieces continue to focus on increasing speed and reducing size, as well as integrating software and data analytics to improve practice efficiency.

With air-driven handpieces, the goal is to derive more power and torque out of them while making them even lighter and smaller. They are quickly reaching that point. DENTALEZ’s Aeras 500 Elite handpiece, an air-driven high-speed dental handpiece with 39 watts of power, is almost as powerful as an electric handpiece. In addition, its built-in RFID system compatibility makes cloud-based, automated tracking and reporting of usage, sterilization, warranty and maintenance information easier than ever.*

With electric dental handpieces, the challenge is how to make the motors and attachments lighter and smaller without losing the power that makes them so efficient. Attention is also being paid to the control unit. Here the focus is on making it more cost-effective by doing more work. For example, one unit that controls multiple handpieces, so the dentist only needs to buy one per operatory, would be a huge cost savings. Making the touchscreen more modern and user friendly is another area of improvement. These advances will help make the busy practitioner even more efficient.

A Future without Dental Handpieces?

Just as current dental handpiece technology is very different from historical innovations, the future of dental handpieces will also carve new paths. In the last few decades, inventors have been working on entirely new methods for treating tooth decay. Technologies such as lasers and air abrasion are being studied for safety and effectiveness. The current consensus is that these technologies may be helpful for patients with dentophobia who have small cavities on the outside surface of the teeth. So far, though, they have not proven effective at treating cavities between or deep within the teeth, so they won’t replace air-driven or electric dental handpieces anytime soon.

Deciding on the Right Dental Handpiece for Your Practice

In the US, more than 50% of the dental handpiece market is still opting for air-driven handpieces, although the electric handpiece segment is growing as more and more dental schools are choosing them as a teaching aid.

Since air-driven and electric dental handpieces will be your bread-and-butter workhorses for the foreseeable future, how should you go about selecting handpieces to outfit your operatories? We have outlined here:

- What are your needs or wants in terms of features?

Is having a smaller, lighter handpiece more important? How about the noise level? Make a list of the features you want and think through what your “must haves” are. This will help you narrow down your options. - What do you have experience with? What are you comfortable with?

Did you use air-driven or electric handpieces in dental school? Chances are you feel most comfortable with what you are familiar with. Use that as your baseline, and if you want to try something new, research first online, and then contact your dental supplier or dental handpiece repair technician for their advice. - What procedures do you do?

Take stock of what procedures you do most often. If you work with children, you may want smaller handpieces. If you work mainly with older patients, you may want handpieces that can handle cutting through old restorations. - What materials are you working with?

Do you use zirconia, cobalt, gold? If so, you’ll need a powerful handpiece to cut through these harder materials. DENTALEZ’s Aeras 500 Series handpieces are a bestselling everyday option that can handle these materials with ease. - What best fits your practice?

There may be other things about your practice that will influence the handpieces you choose. Your budget, other clinicians’ preferences, etc. Many factors can influence your decision.

We are here to answer your questions!

For questions about specific products, reach out to our dedicated and knowledgeable customer service team.

With locations across the globe, our team is here to meet your needs. Find the closest DENTALEZ equipment dealer with our dealer locator.

*With compatible reader system